I’m Matthew Peterson,

A hardworking young engineer with a wide variety of skills, from hands-on electromechanical design, to CAD, to coding. This website is intended to serve as a portfolio, as well as show off interesting personal projects, and it is always being updated.

Personal Projects

I am a tinkerer and my interests vary a lot, but engineering is a part of my personal life as much as my professional. A lot of my design and manufacturing projects, as well as musical instrument projects are shown here. I wish I could put every build/repair project I do here, but it would get long very quickly.

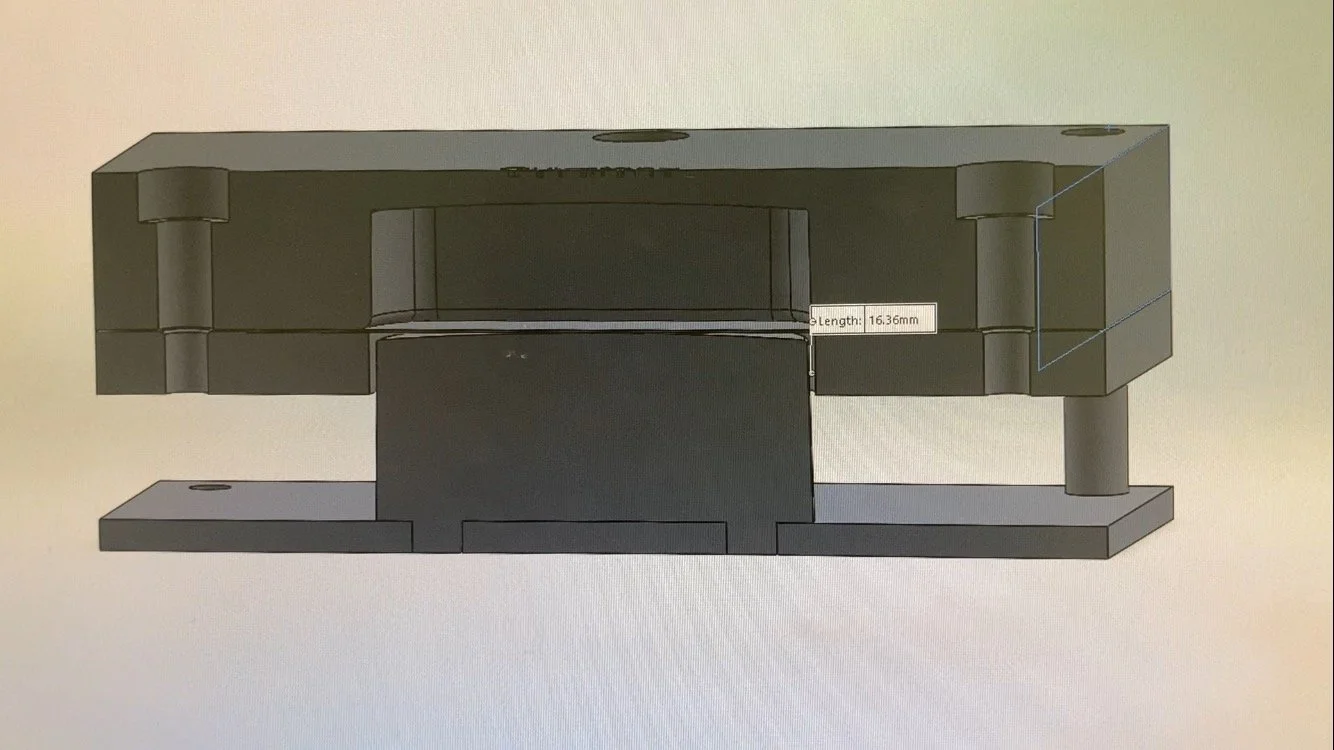

Guyatone LG-50 Pickup stamping (Fall 2024)

As an independent study at NIU, I am working with Guyatone to reproduce the LG50 guitar pickup covers out of brass. I am making an Ansys simulation, and I am making a SolidWorks assembly of the tools to make the real thing on a hydraulic press. The Ansys simulation is a quarter of cover with symmetry BCs for computational efficiency.

LG-50 Stamping Assembly

Since the stamping setup will be a simple hydraulic press, this presented challenges. The material of the blank can wrinkle if there is no blank holder, but the press is for the punch, rather than the blank holder. The solution to this was to use 4 M8 bolts set to a specific torque with a torque wrench. It is slower, but allows for the simple press.

Guitar Amp

(Oct 2024-Present)

This project is in progress right now. I am designing a small Class D Guitar amplifier, with a headphone jack and aux input capability. I have reverse engineered some known designs to take design cues from them, and I am waiting on a preamplifier board from JLCPCB right now. I 3D printed the enclosure on my Voron 0.2 with a fuzzy skin to hide the layers. I will print test pieces for the nicest texture, and it will come together nicely. I had sheet metal parts made with sendcutsend, and I compared bare aluminum to clear anodized and matte black powder coat. I liked this clear anodized, so thats what is shown. That knob is also a placeholder for size, I will use a nicer one on the final version. I will add more info as this progresses.

UPDATE 11/15

I have designed a board with JLCPCB for this, and I am performing thermal testing on the voltage regulator and power amp chip for a class. I also may redesign the preamp to use an STM32 microcontroller and be a digital circuit as opposed to an analog one as it is now. I only showed parts of the schematic that don’t need to stay secret.

Voron 0.2 Build (Sep. 2024)

After returning from DMG MORI in California, I had the itch to build a machine of some sort. Even though my background is more related to metal additive manufacturing, I decided to build a small FDM printer, so I wouldn’t have to outsource 3D prints to rapid prototyping houses. I chose this one to learn every aspect of the build, from frame, to hotend, to power supply, to Klipper software. I spent many hours building and tuning it, and I am still trying to get better, faster results in the engineering plastics it is intended for, namely ASA.I plan on printing some filter housings, and implementing input shaping to this build in the near future. This video was the second build, I repaired the cable management, and a successful build of the guitar amp head can be seen below. That build takes approximately 4-5 hours and has a fuzzy skin, contributing to the time.

DMG MORI (Davis, CA)

I had a great time over the summer in Davis, working on the LASERTEC 30 machine. Brett shows it off well, and I actually poked myself on this exact cactus model once or twice. It was surprisingly sharp. I spent a lot of my time at DMG MORI doing powder sieving related tasks, and assisting operations, as well as recoater work, and engineering drawings of parts. I learned a lot about GD&T from that.

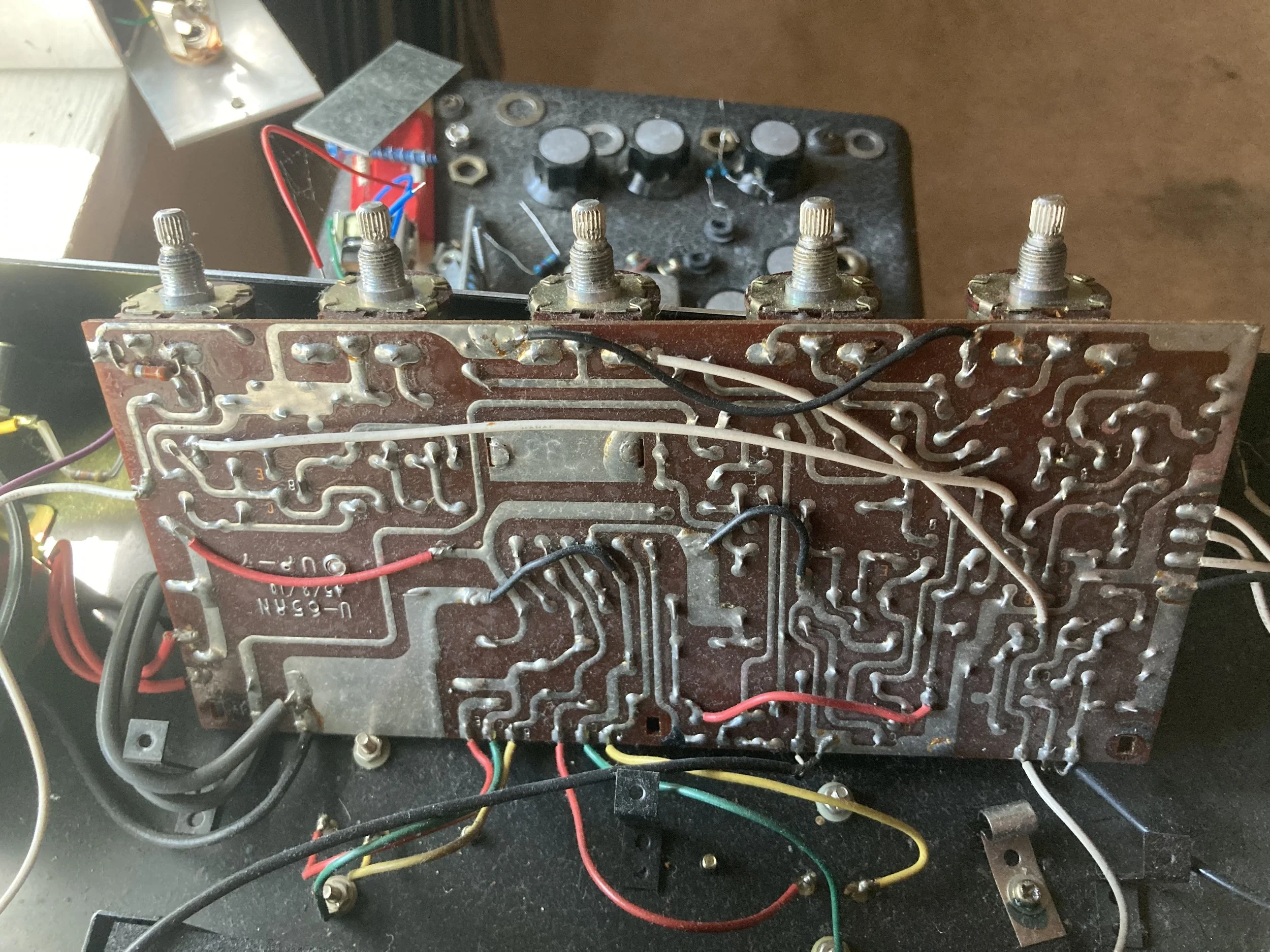

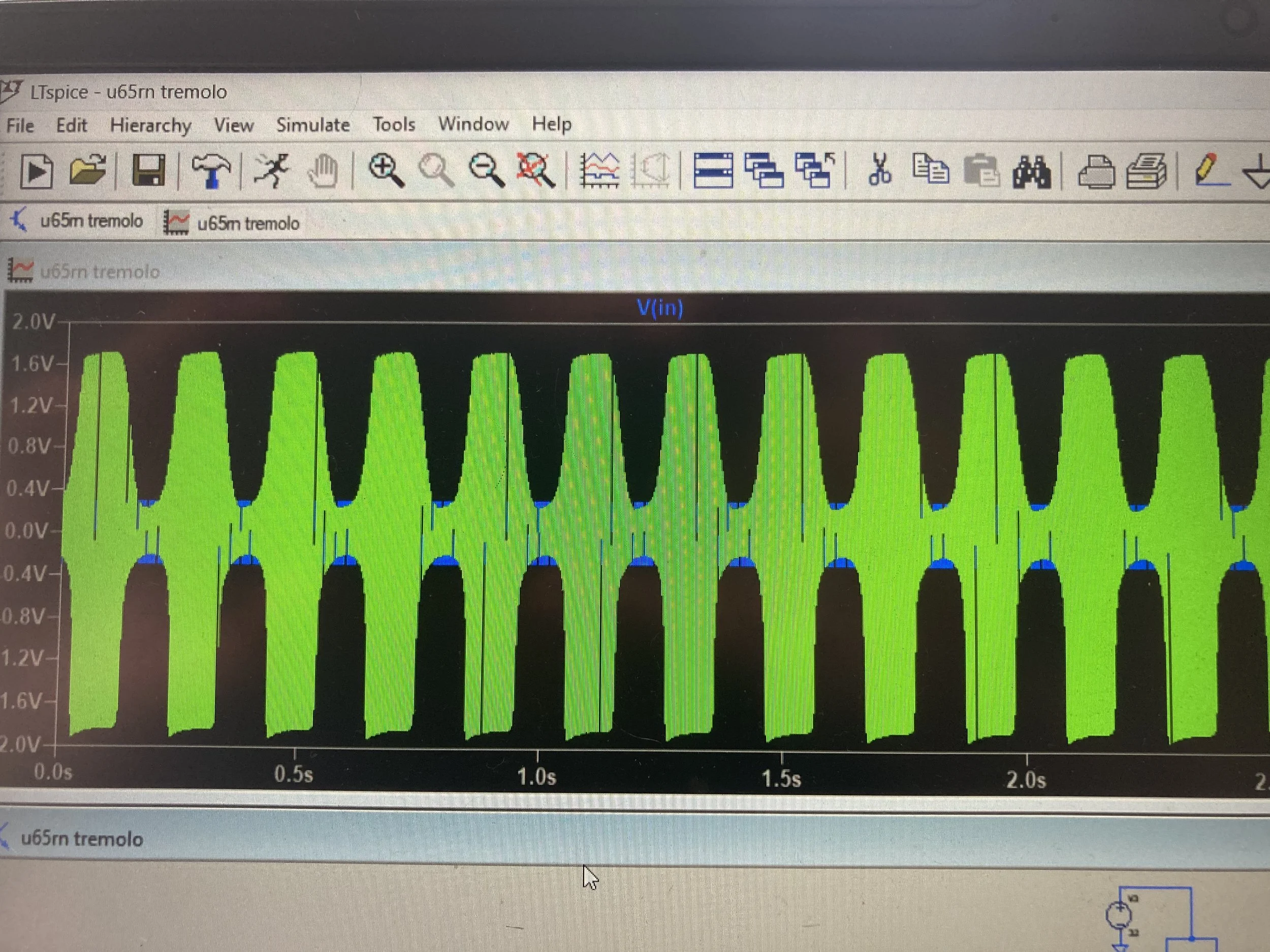

Distortion Pedal Design (2024)

Throughout 2024, I have been working on iterating this distortion pedal design. It is a design not based on anything else, but of course draws from common building blocks. It has some influence from Roland/Boss designs, as well as amplifier design. I think I will call it the Einherjar, after the figures in Norse mythology. It has taught me a lot about putting things into practice together, since in real life, buffers, op amp stages, and filters do not exist in isolation, but all play together. The PCBs I had made by JLCPCB in China, since they are very cheap and I have worked with them in the past. Once I settle on a circuit, I will let the board influence the enclosure design. I plan to design an anodized sheet metal enclosure.

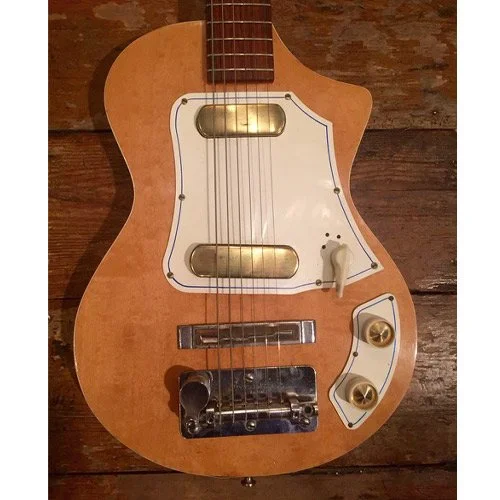

Test Guitar (mid 2023)

As very often happens, I eventually found I needed to make a tool to work on something else, opening a new project. In this case, I was winding more guitar pickups, some low impedance, and some the more traditional high impedance. A high impedance design I made is shown right under the Personal Projects tab. To be able to test these designs, I decided to build a guitar body with holes cut into it for easy removal of pickups, and I devised a mounting arrangement. It works, but I have tinkered with it a lot, and I think I could do this better with what I have learned now. Ordering lasercut parts as a base with magnets is a solution I have in mind. I have broken the nut as well, and need to fix that, so I may come back to this later.

First guitar pedal build, Shin-Ei FY2 clone (Dec. 2021)

At this time, I had a week of my winter break before I was traveling to Berlin, Germany for a few weeks. I was starting to amass my solid state electronics setup, and I wanted to build a simple but interesting guitar pedal. I chose the Shin-Ei FY2, since I love vintage Japanese electric guitar equipment, and I knew it was a simple circuit. I was not disappointed with its harsh fuzz. This pedal is like salt and vinegar chips in that you either love it or hate it. It is actually supposed to sound like that. I am playing through an American style 15W guitar amp that I actually designed myself in late 2023 and breadboarded here. It has a Jfet preamp and class AB power amp.

Contact Me

Interested in working together? Fill out some info and I will be in touch shortly.